How 3D printing could build a home from rubbish

Housing affordability and waste management are two major challenges that Australia is trying to address. The solution to both problems may actually be tied together through the innovations brought around by the 3D printing industry, creating a collaboration between the two fields.

Federal Government figures show that there has been a 78 per cent increase in house prices between 1980 and 2015, with many first home buyers now boxed out of the market. There has also been a 170 per cent increase in waste generation in Australia since 1996.

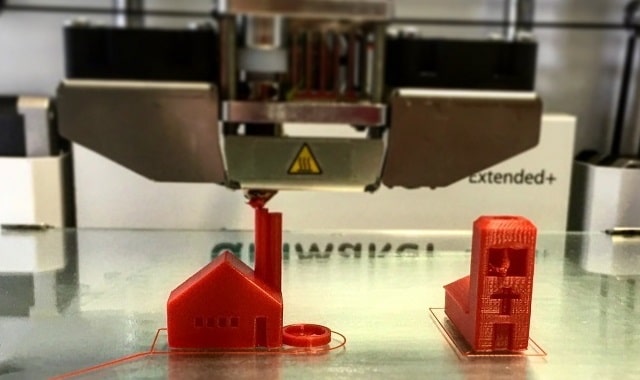

An unorthodox solution could be at hand, though, with companies around the world successfully trialling the production of affordable houses using 3D printers. Some of the projects are even using recycled waste as the raw materials to build them.

Houses are popping up across the globe, built using 3D printers

Global examples of structures being built using 3D printing technology include rudimentary concrete houses in China, as well as offices in Dubai.

Most recently, a residential home in Russia was built this year using a 3D printer by American/Russian company Apis Cotr. It took 24 hours to build and cost just US$10,134.

The process was all done on-site using mobile printing devices which were later removed with a crane so the roof and the internal fixtures could be added.

This company has a vision to help financially disadvantaged people around the world through low cost housing, which is why founder Nikita Chen-yun-tai followed the 3D printing path.

“We want to help people around the world to improve their living conditions,” he said. “That’s why the construction process needs to become fast, efficient and high-quality as well. For this to happen we need to delegate all the hard work to smart machines.”

The house that trash built

The other major benefit that 3D printed houses can have is reducing the volume of plastic that ends up in landfill.

Many companies around the world are already collecting and using household waste products made of plastic to fuel 3D printers, like social enterprise Protoprint.

More than 300 metric tonnes of plastic are produced globally every year, which is why Photoprint founder Sidhant Pai and his parents—Suchismita and Jayant—created their company to convert it into the ‘ink’ needed for 3D printing.

“It added a tremendous amount of value to the waste plastic while still being relatively simple to manufacture at the dump,” he said.

Could we see housing built in Australia using 3D printed recycled waste?

While companies across the globe are already jumping on board this industry innovation, Australia has also seen a glimpse into what is possible in this field at the Melbourne International Flower and Garden Show in 2017.

On display was a team of Australian architects, engineers and robot designers and their product Kooky Cubby, a 3D printed treehouse.

John Hainsworth is the digital leader for the built environment at engineering firm Aurecon and was one of the partners on the Kooky Cubby project.

He sees no reason why we won’t one day see houses built using the technology here in Australia.

“If it doesn’t need to be a thing of beauty and it just needs to be rapidly produced, then it’s only a matter of time before it is seen to be viable,” he said.

-

Subscribe to the latest industry news, insights and AWRE updates.

- Subscribe